Fully crystallized CAD/CAM block made of lithium disilicate with optional characterization firing Single-visit

02/12/2025

Biography

|

Dr. Hendrik Zellerhoff obtained his dental degree at the Friedrich-Alexander University of Erlangen (Germany) in 2003. In 2006, he finished his dissertation under the supervision of Prof. Frankenberg and founded his own practice in Laer (Germany). In 2014, he became in ISCD-certified International Cerec trainer. In 2017, he became a shareholder of DDA Berlin. He is a Member of the DGCZ board since 2019. |

The patient's desire for "fast" and aesthetic restorations is increasing in everyday practice. Many patients are well informed and aware of the possibilities of digital dentistry or chairside treatment. There are various materials for the production of a single-visit restoration (short process time). The new, fully crystallized CAD/CAM block made of lithium disilicate, Initial LiSi Block has recently been added to our options. The ceramic has optimal physical and aesthetic properties without the need for an additional crystallization firing. In this article, the potential of the material is shown by means of an anterior tooth restoration.

The production of indirect restorations in the dental practice has established itself for single elements. Here, the digital workflow offers clear advantages over the conventional method. Often, the preferred option is a single-visit restoration when possible because of the resulting time savings for the patient. The potential is high. Nevertheless, the choice of materials plays an important role. In order to meet the requirements for a single-visit treatment (short procedure time) without having to expect the patient to spend long times in the practice, materials that only need to be polished and not additionally crystallized are advantageous. A crystallization fire in the dental practice takes time. In addition, inaccuracies in peripheral areas could influence the quality of the results.

In case crystallization firing is to be avoided, the choice of materials has so far been limited to hybrid ceramics and glass-ceramics. Alternatives were high-performance composites, so-called hybrid ceramics. New in this environment is now the first fully crystallized lithium disilicate ceramic Initial LiSi Block (GC). This CAD/CAM ceramic block is based on the proven HDM technology (High Density Micronization). The ultrafine crystals simplify the milling of the ceramic, so that Initial LiSi Block is milled in the fully crystallized stage. The crystallization firing step is eliminated and time is saved. But not only the time advantage speaks for this material. Due to the fact that no crystallization firing is necessary, restorations made of Initial LiSi Block impress with their very good fit and edge stability. Even fine-tapered edges remain precisely fitting. Thanks to its high accuracy of fit and aesthetic results, Initial LiSi Block is the ideal, time-saving solution for single-visit restorations. Even in the anterior tooth area, all-ceramic restorations can be made as a harmonious counterpart to the neighboring tooth.

Patient case

Initial situation and choice of material

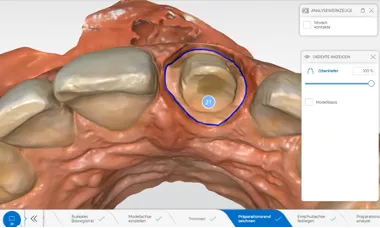

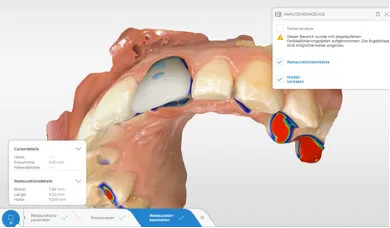

The patient consulted the dental practice with an endodontically pre-treated tooth 21. The tooth built up with composite showed strong discoloration and partially carious lesions. The patient wanted an aesthetic restoration of the tooth and emphasized that this had to be implemented as quickly as possible – in just one appointment. This request, frequently asked by patients, can be granted in case of single tooth restorations using CAD/CAM chairside technology. It was decided to make a single-visit restoration. When choosing a material, the focus is on the time-effective workflow. Nevertheless, the aesthetic demands should be met as well. The aesthetic challenge in this case was the manifold color variance of the neighboring teeth (Fig. 1). Imitating such a tooth shade – especially in the anterior tooth area – requires a material that absorbs the light-optical properties of natural teeth. The choice fell on Initial LiSi Block (Fig. 2). This ceramic has remarkable aesthetic properties and convinces – in addition to the time-saving production – with natural opalescence and a harmonious shade effect.

|

|

|

Fig. 1 Tooth 21 is to be supplied with an all-ceramic crown – single-visit. |

Fig. 2 Material of choice: the fully crystallized lithium disilicate CAD/CAM block ‘Initial LiSi Block’ (GC) |

|

|

|

Fig. 3a and b Pretreatment of tooth 21 and core build-up (GRADIA CORE, GC) |

|

Making the crown in the dental practice

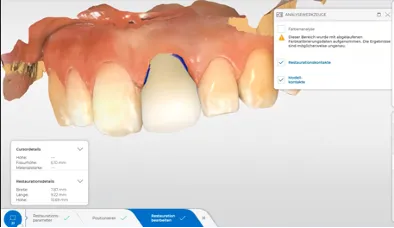

Under local anesthesia, the conservative measures were carried out on tooth 21. The old composite fillings were removed, carious areas eliminated and the tooth was built up (Fig. 3). After the follow-up preparation, the situation could be digitized using an intraoral scanner and the data were imported into the CAD software. The construction of the fully anatomical crown 21 was based on the automatic design proposal (Fig. 4). In the software, fine adaptations of shape, surface and texture as well as the control of the functional conditions were carried out. Then the crown was milled from Initial LiSi Block. The ceramic can be milled quickly. Within a short time, the crown was ready. And while with a conventional lithium disilicate the final material properties are achieved by the additional crystallization firing, Initial LiSi Block is already industrially completely crystallized. Hence, an additional crystallization fire is omitted.

|

|

|

Fig. 4 CAD construction of the crown in the software based on an automatic design proposal |

The preparation of the crown and build-up were followed by a try-in inside the patient's mouth (Fig. 5). The fit was excellent. It turns out that the milling of Initial LiSi Block creates very smooth and precisely fitting edges. Edge areas could be thinned out to the maximum due to the material properties. The surfaces of the crown were homogeneous. This resulted in a shorter post-processing time. In addition, the smooth surface reduces wear on the antagonist in the occlusal contact area.

|

Fig. 5 Try-in of the crown directly after milling (crystallization firing was not required) |

Finalizing the crown and seating

Thanks to the aesthetic properties of the ceramic, natural opalescence was already present; high gloss could be achieved in a few minutes by simple polishing. In the present case, the anterior crown also needed to match the neighboring teeth. The three-dimensional paintable ceramics Initial Lustre Pastes (GC) were used for individualisation. With a few different colors, the crown was optically adapted to the neighboring teeth, fired and completed within a short time. After etching (20 seconds with 5-9% HF) and conditioning (GC Multi PRIMER) the crown’s inner surfaces as well as preparing the tooth surface, the adhesive cementation (GC G-CEM ONE, translucent shade) took place. The result reflected the potential of Initial LiSi Block. The ceramic crown looked alive and natural from within. The color-varying structure of the neighboring teeth was imitated well. It showed a natural surface structure. Within one appointment, the patient was provided with an all-ceramic crown that was more than satisfactory in its aesthetics (Fig. 6).

|

Fig. 6 Single-visit treatment: crown made of GC Initial LiSi Block. The difficult color structure of the neighboring teeth could be optimally reproduced. The before and after pictures show the potential: Within a very short time and in just one appointment, the patient could be taken care of.

|

Result

For single-visit restorations, the choice of material is crucial. High-strength silicate ceramics as CAD/CAM blocks have proven their worth. However, with conventional lithium disilicate ceramics, an additional crystallization firing is necessary to achieve the final physical properties. GC Initial LiSi Block is industrially fully crystallized. A crystallization firing in the dental practice is therefore not necessary. Despite the fact that the material already has its final hardness (408 MPa, biaxially), it can be easily and quickly milled due to the fine crystals in the material’s structure (HDM technology). At the same time, the aesthetic properties impress with their remarkable opalescence. In many cases, polishing is enough to finish a crown. The high gloss is achieved within a few seconds. The production time in this case is about 30 minutes. In challenging cases (e.g. anterior crowns), additional characterization (painting or micro-layering) is possible. This takes only a few minutes. Initial LiSi Block is ideally suited for single-visit high-strength ceramic restorations. For the dental practice, this means a great added value: time savings, cost-effectiveness, patient satisfaction as well as an efficient workflow and reduced use of materials.

Editor’s note: Further information on material properties and processing of Initial LiSi Block and: https://campaigns-gceurope.com/initial-lisi-block/?lang=en